Making of the Japanese Shinkansen

Nine days prior to the opening of the 1964 Tokyo Olympics, Japan unveiled the Shinkansen–a rail system that would transform high-speed travel and come to be known worldwide as the bullet train. After half a century of zero-casualty operations, the Shinkansen remains an engineering marvel and a replicable blueprint for progress.

Over six decades, France, Spain, and China have successfully followed suit and created robust High-Speed Rail (HSR) networks that outperform domestic air travel in efficiency, cost, and carbon footprint. Should countries like the United States and India adopt HSR as a strategic national project?

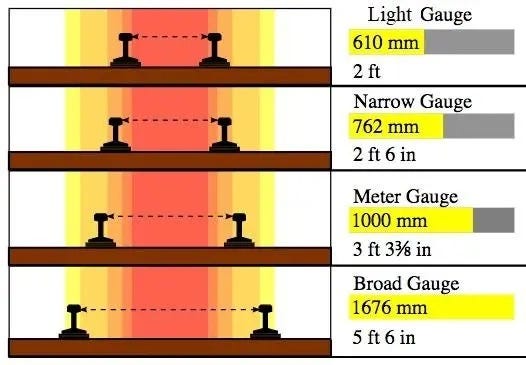

Japan’s efforts toward the “bullet train” began back in 1939 with the Dangan Ressha Project. Traditionally, trains in Japan and around the world ran on narrow gauge tracks. Gauge—the distance between the inner faces of the two rails—is a fundamental concept that determines a train's stability. The entire design and size of a train depends on this measurement. The Dangan Ressha Project began the crucial switch from narrow to wide gauge when World War II forced its suspension.

A decade later, in the attempt of a phoenix-like resurrection from the war’s ashes, Shinji Sogo, the fourth president of Japanese National Railways (JNR), proposed the idea of a super limited express train in 1955. Sogo was inspired by a pioneering engineer, Hideo Shima, who had designed the D51 steam locomotive and numerous railways and transportation systems before and after the war. While the world started believing in the decline of railways amid the rise of air and automobile industries, Shima knew that a network of high-speed trains could lead to a paradigm shift in the way people travel domestically. Sogo pushed the bullet train as a national project, convinced politicians to back the plans, and set an ambitious deadline: the Shinkansen development would be completed in five and a half years.

The project’s budget ballooned from an initial ¥170 billion (~ 1.2 billion USD) to ¥380 billion (~$2.5 billion USD), driven by soaring land prices and rising material costs. The World Bank provided a total of 31 loans from 1953 to 1966 amounting to $862 million. Despite securing funding from the Japanese Government and the World Bank, the financial overruns were too significant to ignore. Skeptics and the opposition doubted the project would ever succeed. Both Sogo and Shima were eventually forced to resign in 1963.

The 0 (zero) series shinkansen was finally put into service in 1964, reaching top speeds of 240-300 kph (149 - 186 mph) on the Tōkaidō main line between Tokyo and Osaka. The transformation was unimaginable: a journey that once took 16-20 hours by steam train, and later 9 hours by conventional electric trains, could now be completed in just 4 hours.

The Tōkaidō Shinkansen, which is the busiest train line in the world, operates upto 12 trains per hour during peak times, with a total of 372 Shinkansen services running per day, carrying 432,000 passengers in total. The Tōkaidō main line generates ¥1.2 trillion ($8.5 billion) annually in revenue.

The trains are manufactured by several major companies:

Hitachi leads electrical systems integration, including the ATC (Automatic Train Control) system.

Kawasaki Heavy Industries Ltd. designs lightweight carbodies. Their carefully designed roof structure cuts noise by 8 dB.

Nippon Sharyo dominates rolling stock components, producing 65% of Japan’s railway wheels and axles.

Kinki Sharyo/J-TREC innovate niche technologies like hydrogen fuel cell auxiliaries and stainless steel carbodies to resist corrosion on coastal routes

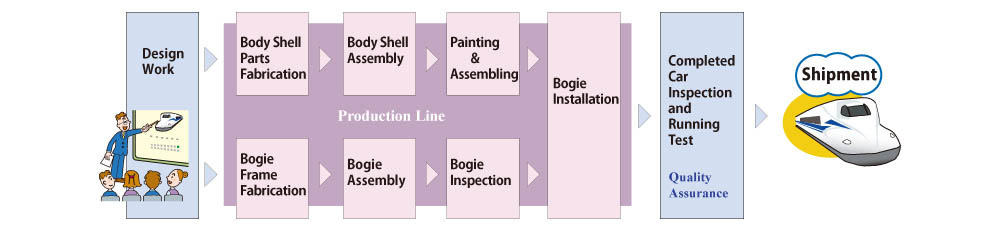

Rather than continuous production, Shinkansen’s manufacturing ecosystem operates on a just-in-time batch production model. A typical production order might include 8-16 trainsets, with manufacturing taking 18-24 months from order to delivery. Each batch integrates incremental innovations like reducing the carbody weight or using silicon carbide (SiC) inverters. Tests like 1,000 km test runs are performed to ensure zero defects before delivery.

The operational management of the entire system falls under four Japan Railway Group companies—Central Japan Railway Company (JR Central), East Japan Railway Company (JR East), West Japan Railway Company (JR West), and Kyushu Japan Railway Company (JR Kyushu).

Physics & Engineering behind the Shinkansen

Gauge and Track Design

As mentioned above, gauge is an important measure for the design and functioning of trains. Conventional trains primarily use Cape/Meter gauge (1,067 mm), which is too narrow to support high-speed trains. Hence, the decision to use Standard gauge (1,435 mm) for the Shinkansen was a crucial engineering decision that led to the bullet train. This choice was driven by some key factors:

Stability: The wider the gauge, higher the train’s resistance to tipping.

High-speed: Standard gauge allows for larger wheel diameters, which can rotate at higher speeds without exceeding any material stress limits.

Load distribution: The wider gauge distributes the train’s weight over a larger area, reducing track weakness and allowing for heavier trains.

Challenge: Hunting Oscillations

One of the most significant engineering challenges in high-speed rail is managing hunting oscillations - a complex motion caused by the interaction of adhesion and inertial forces between the wheelsets and the track. At low speeds, adhesion force is dominant, making it easier for the wheels to stick to the track. At high speeds, adhesion and inertial forces become comparable in magnitude and start oscillating. At very high speeds, like that of the shinkansen, the oscillations can be violent enough to potentially damage or derail the train (curling the tracks).

Why does this happen?

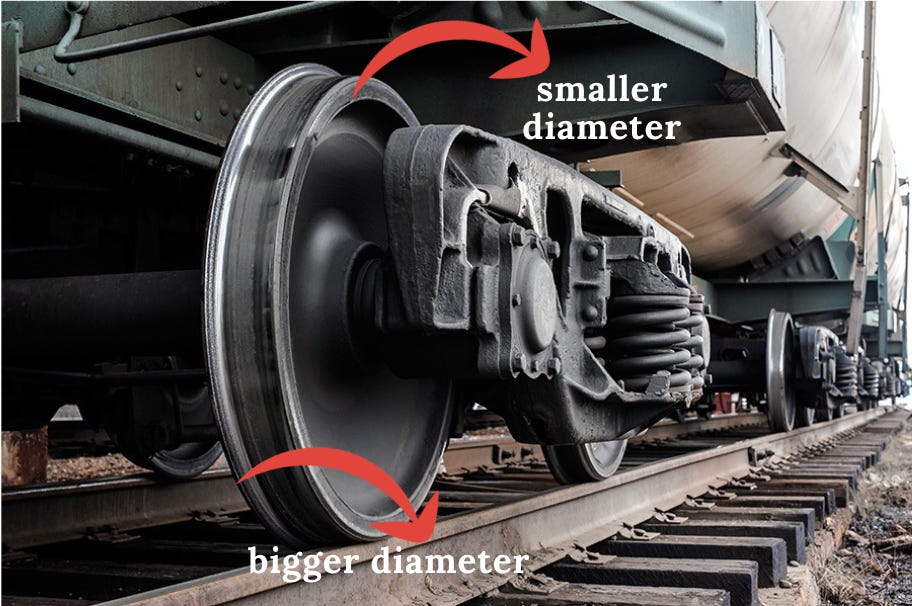

Train wheels are designed with a specific conical shape, known as wheel profile - larger diameter on the inner edge and smaller on the outer. This shape is crucial to help a train curve: when a train turns, the outer wheel needs to travel a longer distance than the inner wheel. The conical profile naturally compensates for this difference, resulting in a smooth curve.

However, this same conical shape creates a challenging side effect at high speeds. At speeds of 200+ kph, the varying wheel diameters can create significant speed differentials between the wheels. This difference causes the wheelset to yaw (rotate side to side), creating a self-reinforcing cycle of oscillations.

Shinkansen engineers tackled this with two key innovations: redesigned bogies (the wheel assemblies beneath each car) and optimized wheel profiles with reduced conicity. The bogies were made lighter yet sturdier, with wider wheelbases for greater stability.

Why train can’t stop like cars

Trains aren’t “big cars”- they’re like momentum dominos governed by Newtonian physics. When a car slams brakes, it can stop in seconds. But a train traveling at the same speed would need kilometers to come to a halt. The difference isn’t just in the size, it’s a carefully orchestrated balance of energy conversion, friction, and steel-on-steel physics.

At 300 km/h, a Shinkansen (~700 tons) has 40 times more kinetic energy than a car (~2 ton) at 120 km/h. Dissipating this energy requires longer distances and highly specialized braking systems.

Where does this energy go?

Shinkansen’s momentum is staggering: This momentum is transferred through three methods—Regenerative braking (converting 70 % of KE into electricity and feeding it back to the grid), Eddy current brakes (using magnetic resistance to slow the train), disc brakes (final stopping via steel discs pressed against wheels)

Conventional high-speed trains rely on steel-on-steel contact, raising a friction problem. Cars run on asphalt surfaces with a coefficient of friction (μ) of approximately 0.7, trains on the other hand run on steel rails with a coefficient of friction (μ) = 0.1. Cars have a 7 times better grip than trains. The Shinkansen’s solution to this problem is to pull the breaks at longer distances. However, in the future, maglev trains, which operate on the principle of magnetic levitation, having no contact with the tracks whatsoever, can potentially have braking performance more comparable to cars. Japan’s maglev line Chūō Shinkansen, is estimated to begin operations by 2027.

Biomimicry and the Tunnel Boom

When a train enters a tunnel at high speeds, it displaces air, creating a pressure wave that travels at the speed of sound (~343 m/s). The wave reflects off the tunnel exit, creating a sonic phenomenon that manifests as a deafening, loud boom. This is commonly known as tunnel boom and is a challenge that engineers need to deal with while designing trains. Tunnel booms can be as loud as 90 dB—equivalent to a lawnmower—disturbing residents and potentially damaging the train’s exterior.

Engineer Eiji Nakatsu, an avid birdwatcher, came up with a solution to counter the tunnel boom. He observed that kingfishers (Alcedo atthis) dive into water at 40 km/h (25 mph) without creating splash or turbulence. Credit goes to their elongated, wedge-shaped beak that minimizes hydrodynamic drag by gradually transitioning from air (low-density medium) to water (high-density medium). This geometry prevents abrupt pressure changes, which Nakatsu realized could analogously help with the Shinkansen’s aerodynamic challenge.

The Shinkansen 500 Series’ 15-meter long nose was redesigned using computational fluid dynamics simulations and wind tunnel tests.

This design change decreased tunnel boom by 30% (90 dB → 70 dB), electricity consumption dropped by 15% despite 10% higher speeds (240 → 270 km/h), and the drag coefficient improved from 0.25 (original bullet shape) to 0.16.

Electric power system in the Shinkansen

The Shinkansen draws power from an overheard catenary system, a network of tensioned wires suspended above the tracks. The standard line draws 25 kV AC (50/60 Hz) and the mini-Shinkansen draws 20 kV AC. The smooth functioning of this system relies on the pantograph. Pantograph is like a single-arm collector that maintains contact with the 25,000-volt overhead wide. Imagine a feather-light touch on a vibrating guitar string while sprinting at 300 km/h.

A lack of contact between the pantograph and the overhead lines could create a plasma arc discharge which is extremely dangerous for the train’s body and can cause casualties. Even a momentary loss of contact at high speeds can create dangerous arcing.

Shinkansen’s pantograph system has evolved significantly since its 1964 debut. Each trainset used to have 6-8 pantographs, but modern designs have reduced it to just 2-3 pantographs per trainset. Modern pantographs use carbon strips instead of metallic ones, providing better wear resistance and contact reliability. They're also equipped with active control systems that adjust the contact force in real-time, responding to changes in speed, wind conditions, and wire height. Some models even incorporate noise-reduction features, as pantograph noise becomes a real problem at speeds above 200 km/h.

Production process

From the nose cone assembly to final testing, every step of the production process reflects Japan’s philosophy of monozukuri (the art of making things). Japan’s apprenticeship programs produce technicians like Nippon Sharyo’s welding specialists (1 defect per 10,000 welds vs 50 in EU). These apprenticeship programs are generally 2.5 years long, combining metallurgy, CAD, and hands-on training, along with in-house certifications for tasks like ultrasonic axle testing.

Japan's rail manufacturing giants—Kawasaki Heavy Industries, Hitachi, and Nippon Sharyo—operate 500,000+ sq. km facilities dedicated to producing these remarkable bullet trains.

The manufacturing process starts with the design phase. 3D CAD is used to create blueprints which go through structural strength, aerodynamic, and performance analysis. Each trainset comprises over 10,000 components.

Carbody Fabrication

The carbody is the skeleton for the Shinkansen, consisting of five mains structures: the nose, roof, side panels, underframe, and end structure. Each part undergoes a specialized fabrication process.

Nose Structure

Nose is one of the most complex parts due to its kingfisher-like break shape. Aluminum ribs are mounted onto jigs for precise alignment. The modern N700S Shinkansens use double-skin aluminum extrusions that are both light and sturdy. 3D-curved exterior panels are shaped using 2,000-ton hydraulic presses and are welded to the framework to create a seamless surface. Complicated shapes are formed by hand with hammers.

Roof, Side structures, underframe, and rear

The remaining structures follow a similar production process, utilizing double-skin structures made from large-scale aluminum extrusions. The roof integrates heating, ventilation, and air conditioning ducts while providing insulation against noise and temperature changes.

Side panels are fabricated using advanced welding machines capable of continuous, long welding to eliminate gaps. Windows are precisely cut and finished from the welded side panels.

The underframe houses critical components like air pipes, electrical wiring, and bogies. After assembly, it is transferred to the next stage using overhead cranes.

Assembly of the Carbody Shell

Once all individual components are fabricated, they are welded together to form a complete carbody shell. Both robotic welding and manual welding are used for precision and intricate sections. The assembled shell is then inspected for structural integrity before moving to the next phase.

Testing and Quality control

Over 7,000 individual quality checks and multiple wind tunnel tests are performed before a train is certified for operation. Each bogie undergoes rigorous testing, including load simulations and rotational tests at speeds up to 350 km/hr.

High-speed rail enabled the formation of a single high-speed megaregion, integrating businesses, labor markets, and industries along the route.

By the 1970s, the economic impact was undeniable. Cities along the Shinkansen line saw GDP growth accelerate, and Japan’s manufacturing sector flourished as workers and goods moved more efficiently. The train also helped Japan pioneer just-in-time production, a key component of its later industrial dominance. Unlike in the United States—where interstate highways fueled suburban sprawl—the Shinkansen reinforced the centrality of high-density urban hubs, making Japan’s cities some of the most productive in the world. So much good can happen when we make travel simpler and cheaper for millions of people.

The Shinkansen emits just 4.3 kg of CO₂ per passenger per trip—92% less than domestic flights on comparable routes—and consumes only 0.029 kWh per seat-kilometer, making it one of the most energy-efficient modes of transport.

But if the Shinkansen is such a success, why hasn’t the world adopted it more widely?

In California, plans for a high-speed rail system connecting Los Angeles and San Francisco has been plagued by delays and cost overruns. Decades of automobile-centric policy, weak state capacity, and decentralized infrastructure planning have made large-scale rail projects nearly impossible. India’s Mumbai to Amritsar High-Speed Rail (MAHSR) project is estimated to cost ₹1.1 lakh crore (~$13 billion USD).

China, on the other hand, has a high-speed rail expansion—spanning over 42,000 km—demonstrates how a strong state-led approach can deliver massive infrastructure projects. However, China’s approach relies on subsidized state-backed lending, whereas Japan’s Shinkansen was a carefully engineered commercial success. France’s TGV is also another successful example of HSRs.

For nations looking to build high-speed rail today, the key lesson from Japan isn’t just the technology—it’s the governance model. The Shinkansen succeeded because Japan made it a national priority, coordinated across government and industry, and committed to long-term investment.

The Shinkansen is proof of concept for ambitious, state-driven infrastructure, a reminder that big projects require long-term vision, institutional competence, and political will.

The question remains: can we still build like Japan did in the 1960s?

Further Readings:

https://dranevitan.blogspot.com/2011/07/production-processes-of-shinkansen.html

https://newrepublic.com/article/70446/high-speed-rail-getting-the-assumptions-right

https://blogs.worldbank.org/en/transport/should-countries-invest-high-speed-rail

https://immersive.kyodonews.net/shinkansen-part-1-of-2/index.html